I would like to explain the difference of boiler types and its features. I will classify boiler types as Pulverized Coal Boiler, Circulating Fluidized Bed Boiler (CFB) and Stoker Fired Boiler. CFB is a more specific classification of fluidized bed boilers. There is also another type called BFB for fluidized bed boilers. My understanding is that the difference between CFB and BFB lies in whether or not the sand is circulated (CFB has higher efficiency than BFB). However, since I am not familiar with BFB, I will use CFB as the basis for comparison here.

I stay in Malaysia now. Malaysia have abundant resource of biomass fuel. I would like to spotlight on how can biomass be fired on each types of boilers.

Potential of Biomass in Malaysia

Malaysia have abundant resource of biomass(refer page p.17-19 following link).

https://www.kpk.gov.my/kpk/images/mpi_biomass/27122023-National_Biomass_Action_Plan.pdf

Total biomass quantities (Year 2022) are182.6 million ton per year. Let’s assume we completely utilize all this biomass amount. In that case, based on my assumption calculation it possible to produce approximate 720,000 MWh per day . That is almost close to double of Peninsular Malaysia demand.

Of course, it is impossible to fully utilize by supply chain issues etc. However even utilizing 10% of this total resource, it shall be able to replace 3 units of 1000MW coal firer power plants.

Comparisons of boiler type

| Firing system | Capacity | Fuel usage | Plant Efficiency | |

| PCB | Coal pulverized in a mill and burned at a burner system | 50~1000MW | Mainly coal but able to mix biomass pellets | 35~40% |

| CFB | Fuel supplied into a hot fluidized sand and burned being suspended and mixed by air | 5~600 MW | Coal and various biomass fuels (100% biomass possible) | 25~35% |

| Stoker fired | Fuel burned one moving grate | 5~50 MW | Coal and various biomass fuels (100% biomass possible) | 10~20% |

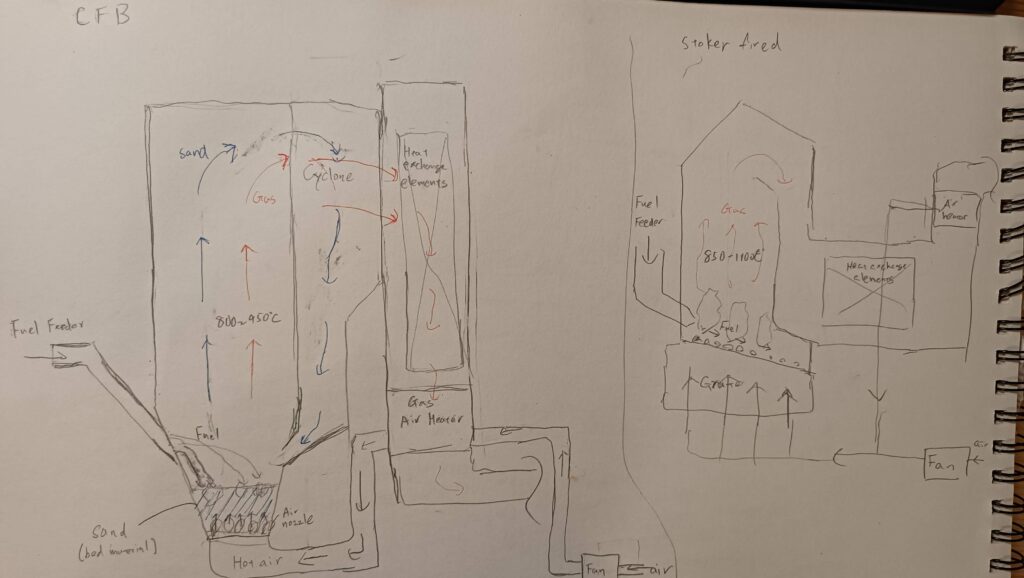

It is easier to understand the concept by images that words. So I made a easy concept diagram. Please understand not covers 100% correct and complete system.

Which boiler type to use ?

PCB is most suitable if you plan to burn coal and need high capacity over 500MW. CFB also may be considered but I understand that operation cost will be higher than the PCB boiler at large capacity. Because the fuel is fed mechanically and will be challenging to distribute the fuel compared to pneumatically fed PCB.

But if you plan to utilize biomass fuel, CFB or stoker fired boiler will be the option. Stoker fired boiler initial cost shall be way lower than CFB. However, CFB shall be more efficient and scale up than stoker fired boilers.

I know that the majority of biomass boilers in Malaysia are stoker fired boilers. Never heard of CFB. I would like to study why next time..

Questions to answer next time

- In what type of boilers and supply chain case, biomass fuels need to be in pellets ?

- Which type of boiler is appropriate for various types of biomass and method of processing ?

- Why are there no CFB plants in Malaysia ?